Metal Fabrication

YOUR FABRICATION SOLUTION

Teske Manufacturing is your sheet metal fabrication partner for excellence and reliability. We take great pride in providing our clients with expertise ranging from design review to precision laser cutting. Whatever you can dream up, Teske Manufacturing can meet your fabrication needs.

INDUSTRIES WE SERVE

Teske Manufacturing is equipped to handle fabrication needs for a variety of applications and industries including agribusiness, constr

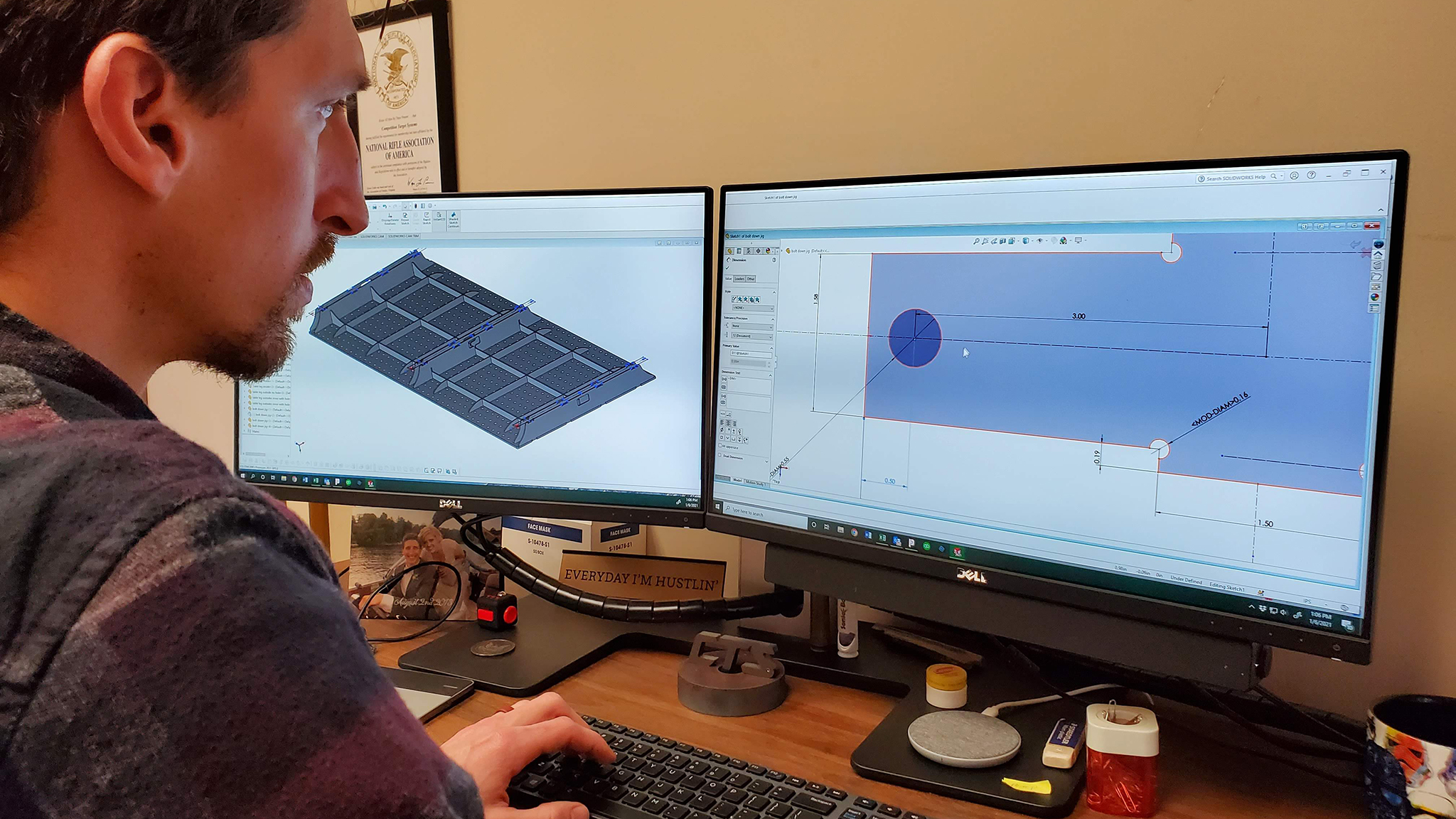

Design Review

Careful Design Review helps reduce waste and lower costs.

With the design review process, Teske MFG. can be involved as much or as little as the client wants. We work hands-on with our clients to find efficiencies in drawings to help save them money.

Additionally, Teske MFG. stays up-to-date with the latest computer software to constantly improve design, help reduce waste and lower costs.

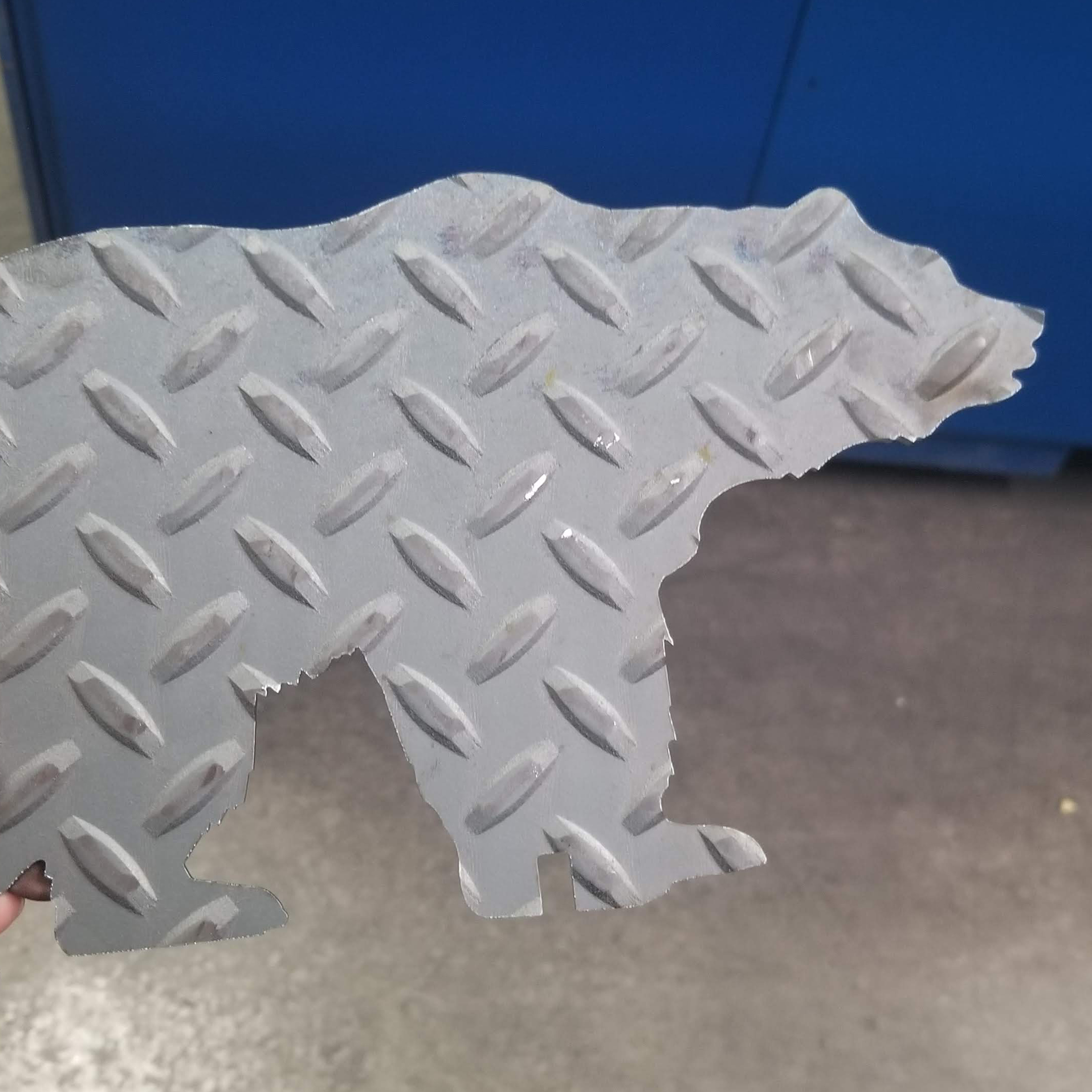

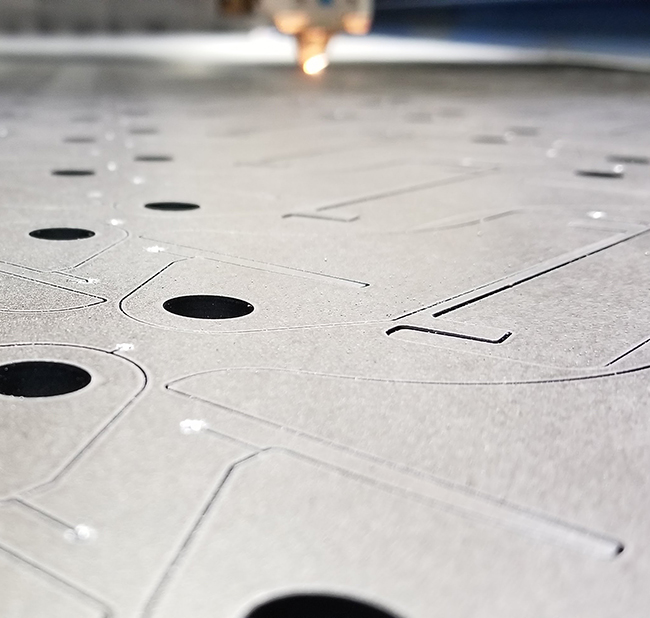

Cutting

Precision is in every cut.

Precision and expertise drive Teske MFG.’s ability to utilize CO2 laser cutting technology resulting in top-quality craftsmanship with superior surface finishes.

Trumpf Trumatic L3030 CO2

- 60“ x 120“ table size

- Steel thickness up to .75“ thick

- Aluminum up to .25“ thick

- Stainless steel up to .375“ thick

Hydmech S-20A

- Full-auto horizontal pivot-style band saw

- Capacity: 13” H x 18” W

- 60 degree pivoting saw head for cutting angles

- 5 HP true direct blade drive – no belts/pulleys

- Automatic PLC, touch screen control

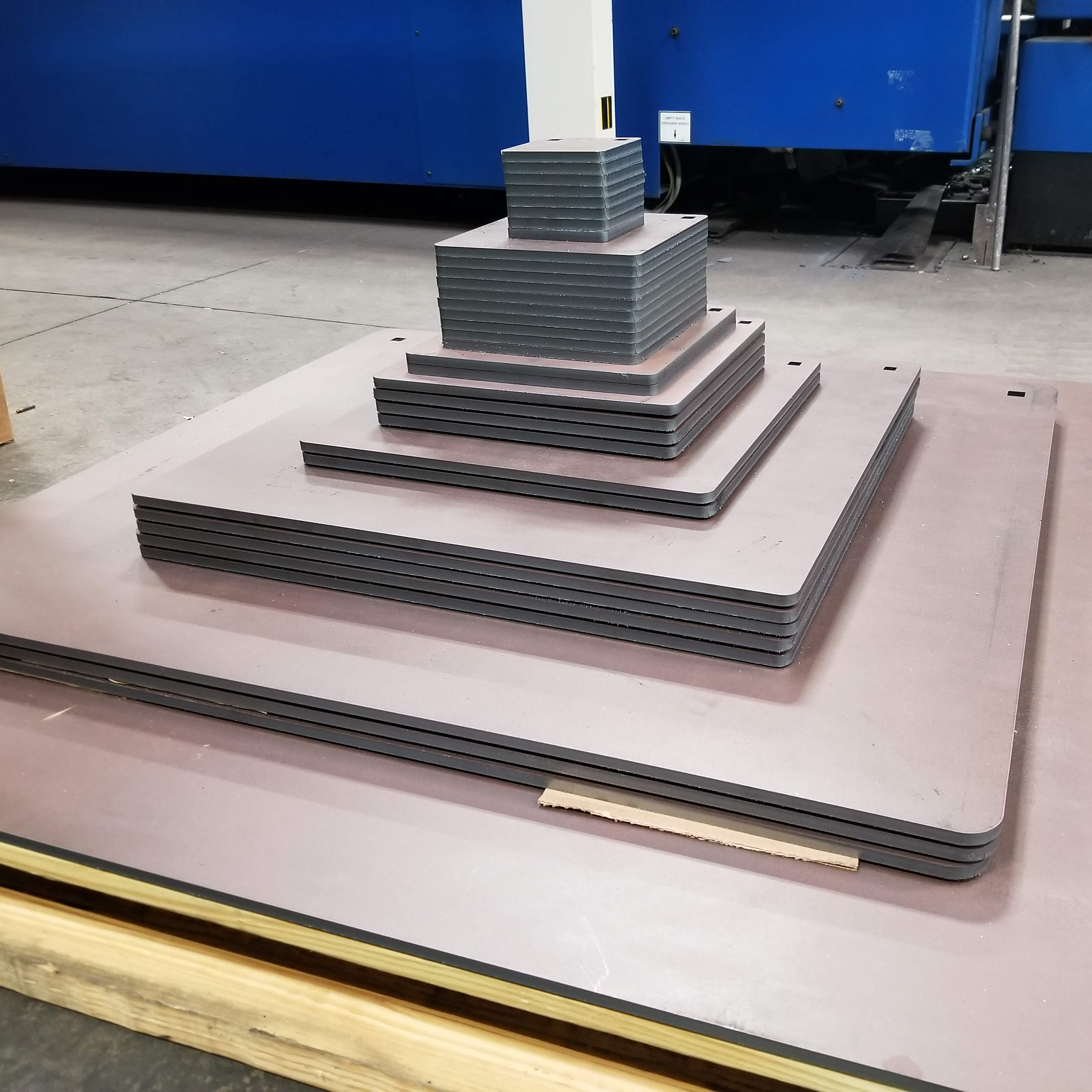

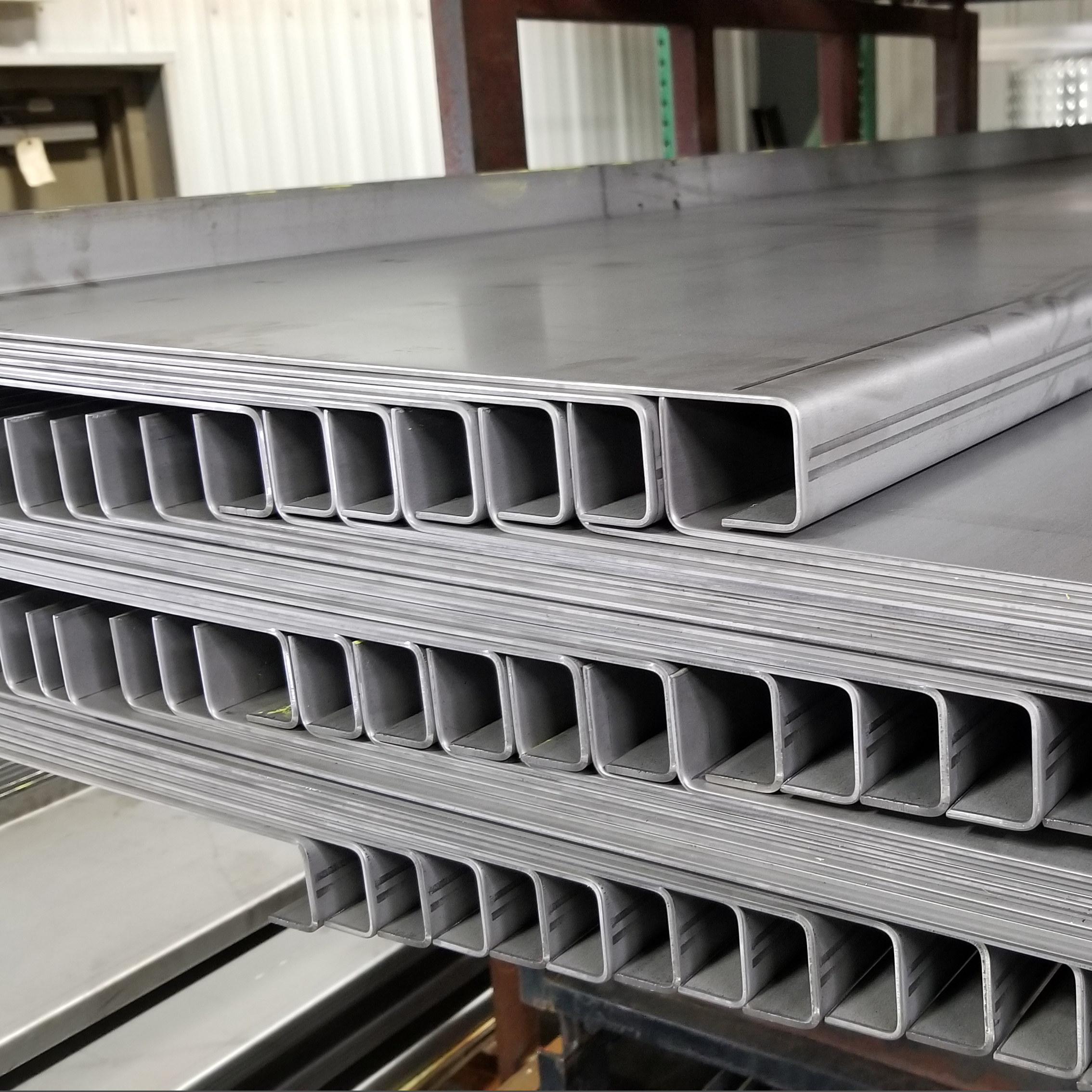

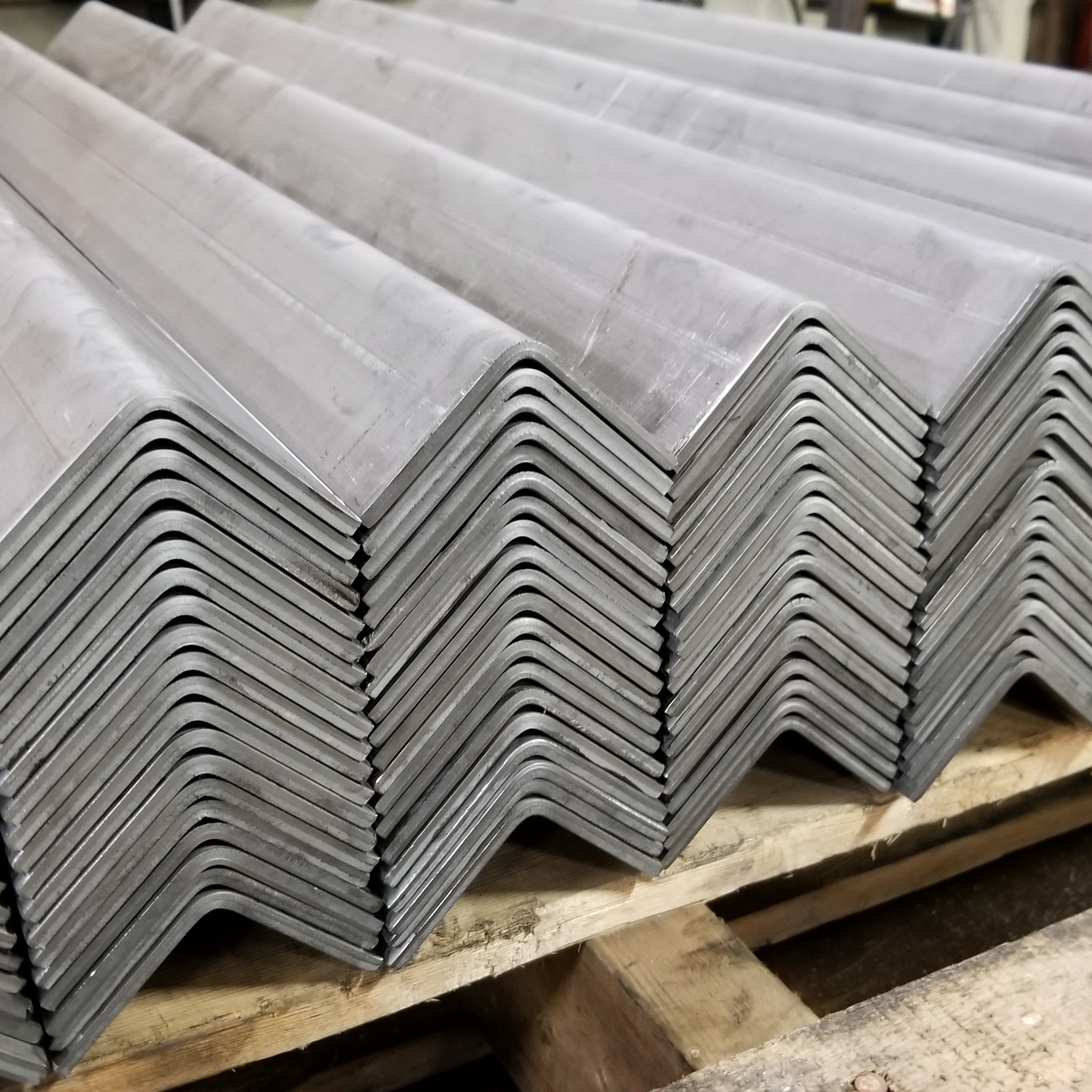

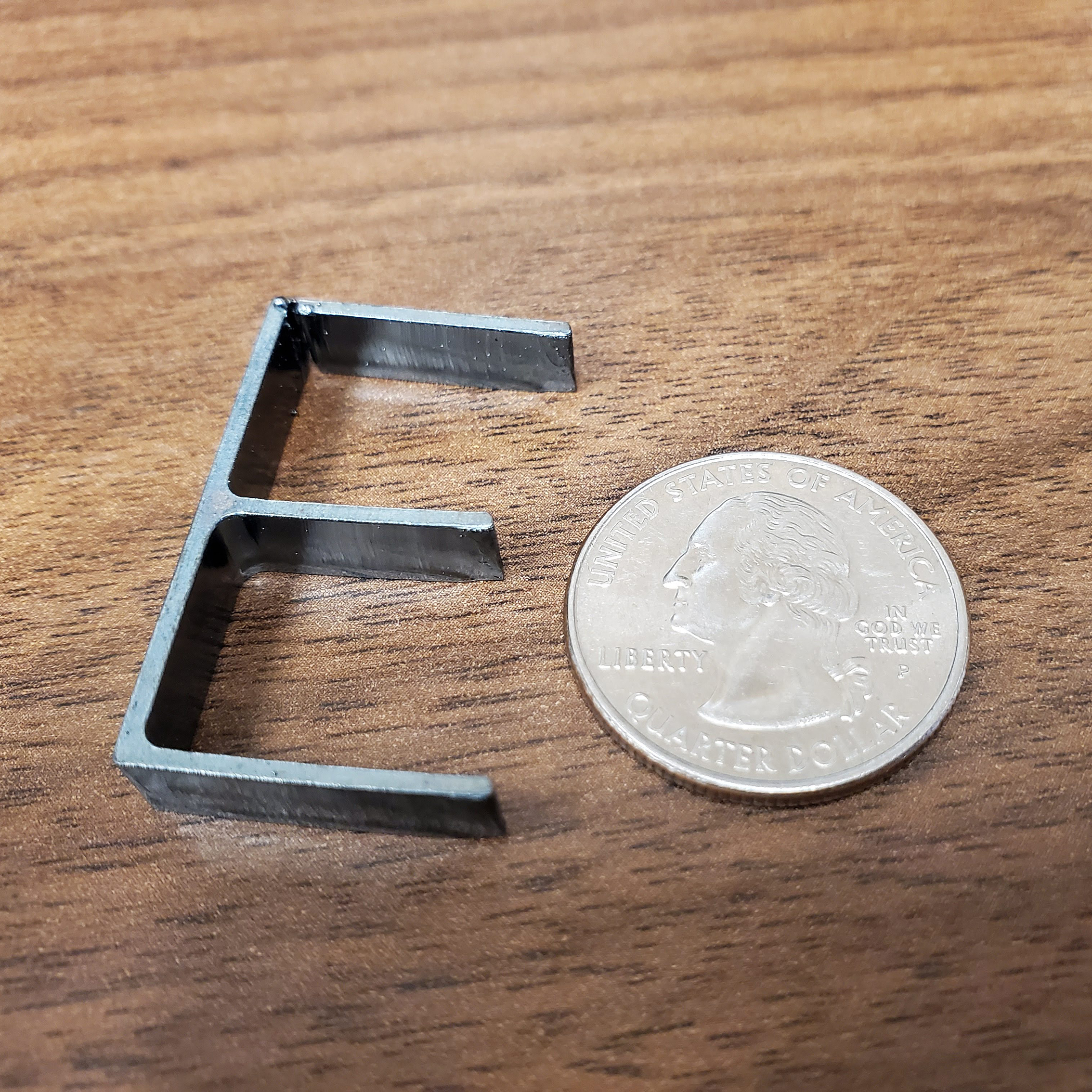

Forming

Forming to take on new shape.

State-of-the-art technology allows Teske MFG. to apply a pressing force to material—allowing it to bend and form—to match the size and shape of the die and maintaining that shape forever.

Amada HM 2204

- 14‘ material capacity

- 243 tonnage (US)

- Variable slit crown bed—ensuring angles are consistent across the entire bed length

- Higher rigidity and larger open height

- Multiple axis back gauge

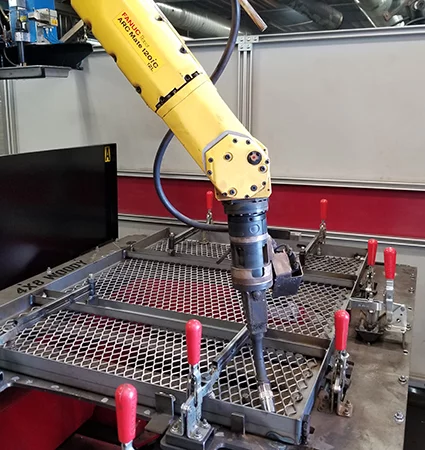

Welding

Welding expertise resulting in a reliable bond.

Teske MFG. is your source for welding—both robotic and manual—for a wide variety of metals.

Fanuc Arc Mate 120ic

- Lincoln R450 power wave power supply

- Single load/unload two-station H-frame robotic welding system

- Dual 10‘ x 60″ diameter rotating jig frames

- Precision laser eye touch sense

- 1,000 lbs weight capacity per station

Advanced Process Lincoln S350 Power Wave Welders

- MIG welding steel and aluminum

- Wide range of material thickness

- Multiple welding stations

- Flexible for large and small job runs

Lincoln Electric Fabmate

- Arc Mate 100id Fanuc Arm

- Power Wave R450 Power Supply

- Magnum Pro Robotic Torch

Additional Services

More fabrication services to meet your needs.

In addition to design review, cutting, forming and welding, Teske MFG. has additional services for your fabrication needs.

Drilling & Tapping

- 5/16″ tap capacity in mild steel

Assembly

Packaging

Stocking

Our Projects

Take a Look

Get a Quote

Let’s get started today!

We want to hear from you. Please provide a little detail about your project and your contact info and we’ll be in touch.